Flex fuel sensors measure ethanol content. They can be used in the FPR return line. But for improved accuracy and faster response times, the sensor should be plumbed upstream of the fuel injectors in the feed line. In this case, expect to see up to a ~10psi pressure drop if multiple pumps are used with a high-powered engine.

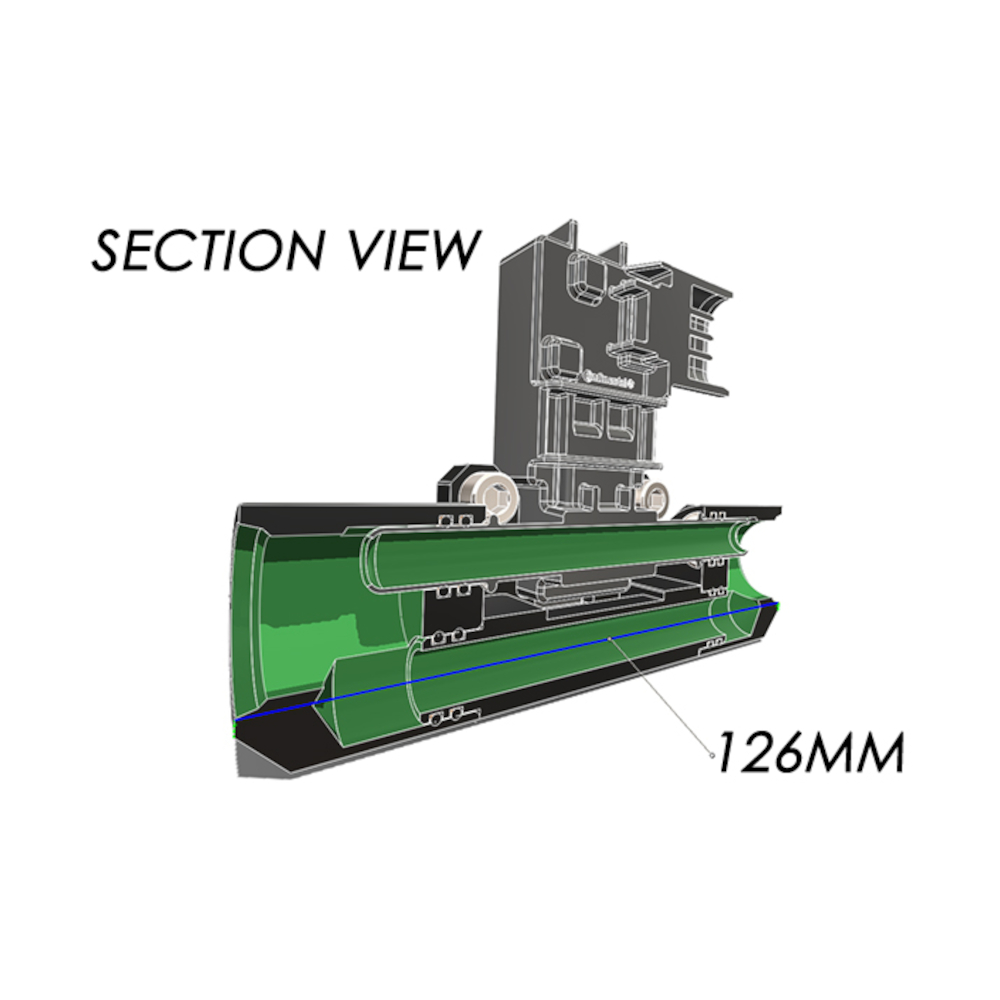

As shown above, the Radium Engineering adapter splits the fuel flow into an auxiliary passage parallel to the sensor. Because the flex fuel sensor is directly inline with the fuel flow path, it will read the incoming ethanol content at high and low engine demands. Traditionally this additional flow path could be accomplished with hose and y-adapter fittings. However, the Radium Split-Flow Flex Fuel Sensor Adapter is less complicated, considerably compact, and provides a mounting solution for the popular GM 13577429 flex fuel sensor (shown below).

Two M6x1.0mm socket head bolts are provided for mounting.

Additionally, the position of the sensor can be rotated at any given time even when mounted and plumbed.

This is great for proper spacing with surrounding components.

SENSOR COMPATIBILITY

The Radium Engineering Split-Flow Flex Fuel Adapter was designed to be compatible with multiple sensors, as described below.

1. GM P/N: 13577379

Compatible with included mount (shown below).

2. GM P/N: 13577429

This sensor already has 3 useable mounting holes. The provided mount cannot be used.

3. GM P/N: 13577394

This sensor already has 3 useable mounting holes. The provided mount cannot be used. For assembly, this sensor (shown above) requires a minor modification described in the instructions.

FEATURES

-4pc billet 6061 aluminum construction

-Black anodized and laser engraved

-10AN (5/8″) equivalent flow rate

-Can be used on fuel feed or return line

-8 double FKM O-rings (primary and backup)

-Stainless steel metric hardware

Reviews

There are no reviews yet.