The 857564-6001 Garrett intercooler directly fits the 2015+ 2.3L Ecoboost Mustang in the stock location and can support up to 600 horsepower. This intercooler assembly leverages Garrett’s extensive automotive and aerospace experience to offer the market a differentiated product.

The aluminum core features advanced offset fin design and vacuum brazed bar-and-plate construction resulting in superior thermal and fatigue performance. CFD optimized cast aluminum end tanks reduces recirculation and maximizes flow. The complete assembly results in up to a 30% reduction in pressure drop and up to a 40 degree reduction in charge air temperature.

The intercooler installs in two and a half hours using basic hand tools and can reuse the factory hoses, clamps, and bolts. Slightly elongated inlet and outlet ports create a secure surface for hose attachment reducing the chance of detachment on higher horsepower applications while maintaining compatibility with OEM hoses and aftermarket charge pipes.

Features

- Rated up to 600 horsepower

- Aluminum core featuring advanced offset fin design and vacuum brazed bar-and-plate construction

- TIG welded CFD optimized cast aluminum end tanks

- 60% larger core than stock

- Up to a 40 degree reduction in inlet temperatures

- Up to a 30% reduction in pressure drop

- Elongated inlet and outlet ports for improved hose attachment

Superior fatigue performance

To maximize the available space and cooling potential, the Garrett intercooler core is 60% larger than stock and features advanced offset fin design and vacuum brazed bar-and-plate construction resulting in superior fatigue performance and up to a 40 degree reduction in charge air temperature.

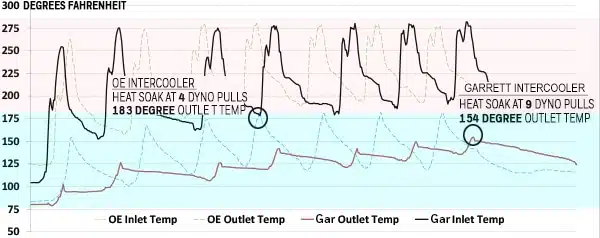

A stock 2016 2.3L EcoBoost Mustang was used to perform consecutive dyno pull comparisons to simulate on-track conditions with the Garrett intercooler and the OE intercooler. In the chart above, each peak represents one dyno pull. The top peaks show inlet air temperatures which remain consistent around 275 degrees while the bottom peaks reflect outlet air temperatures going into the engine.

Heat/soak saturation

Heat soak/saturation identifies the limit at which an intercooler can no longer reduce charge air temperatures going into the engine. Looking at the chart we can see that both intercoolers reach heat saturation at significantly different times and significantly different temperatures.

Based on this test, the OE intercooler reached a max outlet temperature of 183 degrees during its fourth pull; whereas the Honeywll intercooler took 9 dyno pulls to heat saturate and reached a maximum outlet temperature of 154 degrees.

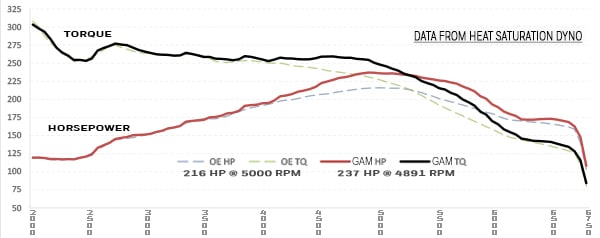

The graph depicts horsepower and torque at full heat saturation. With the OE intercooler installed, the 2.3L engine produced 216HP at 5000 RPM. Garrett’s C.A.R.B. approved intercooler upgrade produced 237HP at 4891 RPM.

Intercooler upgrade

Increasing the efficiency of the air cooling system enables the engine to produce higher peak values during the hottest conditions by delivering cooler air to the engine and prolonging the negative effects of heat saturation. This intercooler upgrade installs in two and a half hours using basic hand tools and reuses the factory hoses, clamps, and bolts. Elongated inlet and outlet ports create a more secure surface for hose attachment reducing the chance of detachment on higher horsepower applications while maintaining compatibility with OEM hoses and charge pipes.

Reviews

There are no reviews yet.