Welcome to the beginning of the end for Project BlueSky, where we will talk about what we all love to talk about, power! However, before we get on to power, let’s talk about how the car will handle this newly unlocked power via the Kraftwerks Supercharger kit. With Project BlueSky we decided to upgrade the clutch and flywheel system to the Clutchmasters FX300 kit. The owner of this car intended this car to be a fun, fast and reliable street car first and foremost. It was not going to see trackday after trackday and with that in mind we chose the FX300 kit – a kit designed for a medium powered car that will see most of its life on the street. The kit offers slightly heavier clutch operation while enhancing the reliability, longevity and clutch pedal feel. Let’s take a look at the Clutchmasters FX300 kit.

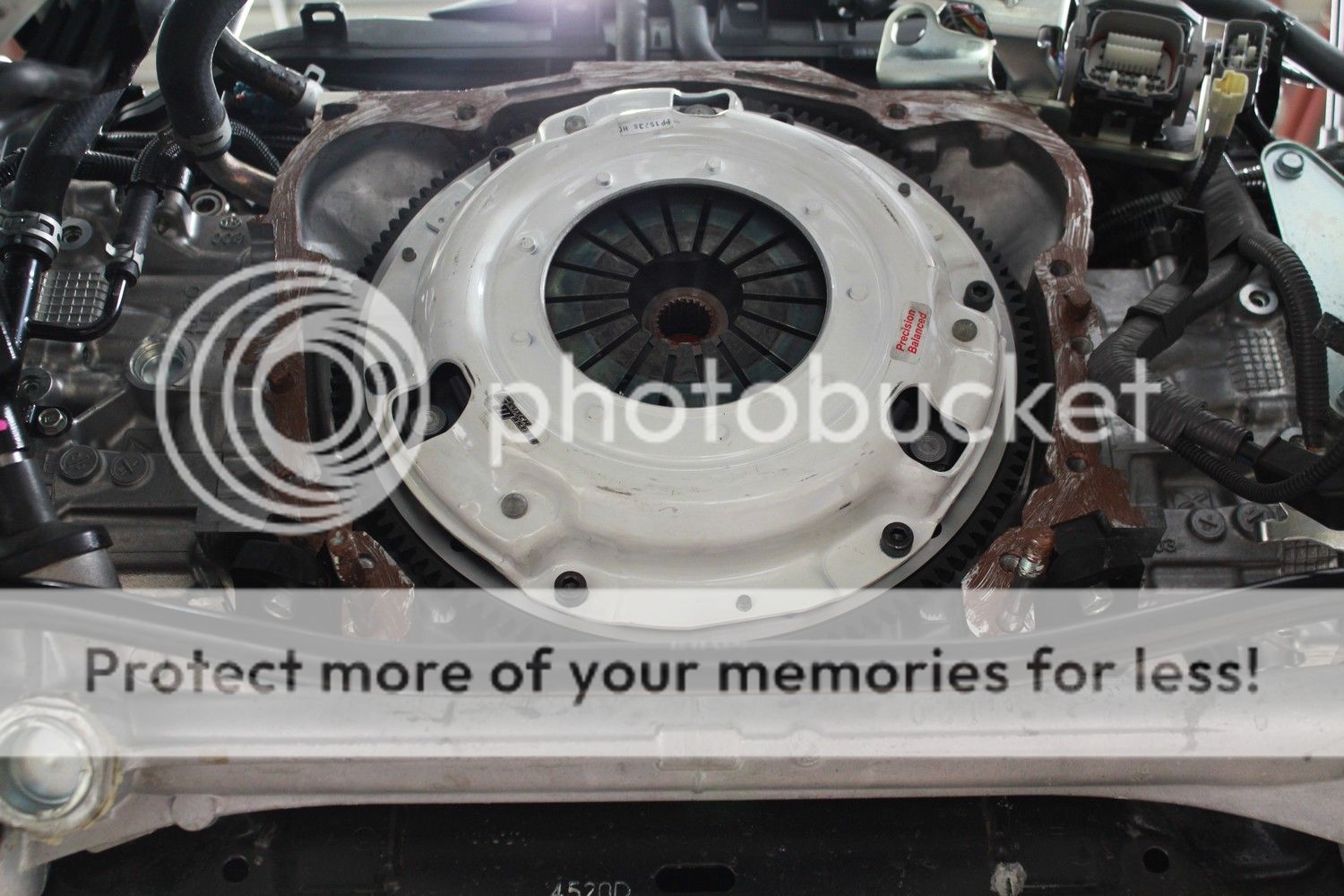

Below you will see from top to bottom the steel back segmented Kevlar disc mated to the flywheel, next you will see what the stock cltuch/flywheel set up looks like, and lastly, the kit installed and ready for the gearbox to go back on. Although we will never see it, it’s nice that the kit has a white clutch cover which matches the white car.

So now we know how the car will handle this new power reliably while also improving longevity and clutch feel. It’s time to get into the real bits and bobs of the Krafwerks Rotrex Supercharger. What we like about the Rotrex supercharger is that of a Ultra high efficiency and silent operation while it also operates at low temps. Moreover, the self containted lubrication and cooling system also adds to the reliability and simplicity of the system.

In the first post we looked at some nice up close photos of the Rotrex system including a photo of the compressor wheel fins. This time let’s look at how Kraftwerks has created this beautiful mounting plate that is CNC’d from one piece aluminum. Kraftwerks purposely decided to create an offset mount for the supercharger, meaning the mounting plate mounts the supercharger slightly off centre from the centralized throttle body we see on the FRS/BRZ engine. There are advantages for this design. This offset location allows for greater clearance around belts, thus reducing chances for rubbing, allows for simple and more efficient tubing layout, and it allows the air intake to have sufficient room to reach the utmost front and lowest part of the car creating as much as ‘cold air’ system as possible. Let’s take a look at a few photos. The first photo shows just how beatifuly crafted the mounting plate is, followed by preliminary installation into the engine. Then we get a better close up look of the location and another view from the left side showing protrusion and again just the quality, fit, and finish of the KW kit.

At this stage it was pretty straight forward. Everything began to come together nicely as shown in the photos below. Apart from the Skunk2 radiator not working with the KW supplied front mount intercooler, everything else was smooth as butter. This is not by coincidence as KW specifically designed this kit to be have a clean almost stock like look. It is important to us at Touge Tuning that off the shelf kits have gone through the proper R&D before being released to the public. We only recommend the best to our customers. With the KW kit it is clear they have done their homework, above and beyond. There is absolutely no cutting, drilling or welding required to install their kit and when installed the engine bay looks very clean and professional. The Rotrex C38 unit supplied with this kit is a proven unit KW has been using in various Honda applications for several years where we also touched on in Part 1 just how good the Rotrex brand is. Now let us bask at the photos of a completed Kraftwerks Rotrex C38 Supercharger kit for the BRZ/FRS.

As you can see from the photos above, the kit is absolutely superb. Adding just that nice touch of “oooooo, what do we have here” when you pop the hood. If the piping and Rotrex compressor wheel was coated black, most people would not think the engine was even touched. We can’t stress how much we love how clean the KW kit sits inside the engine bay of the FRS/BRZ – it’s absolute harmony. With the front bumper back on, the keen observer will see that this is no ordinary BRZ as the KW logo on the FMIC peaks out from the slats of the front bumper, a very nice subtle touch.

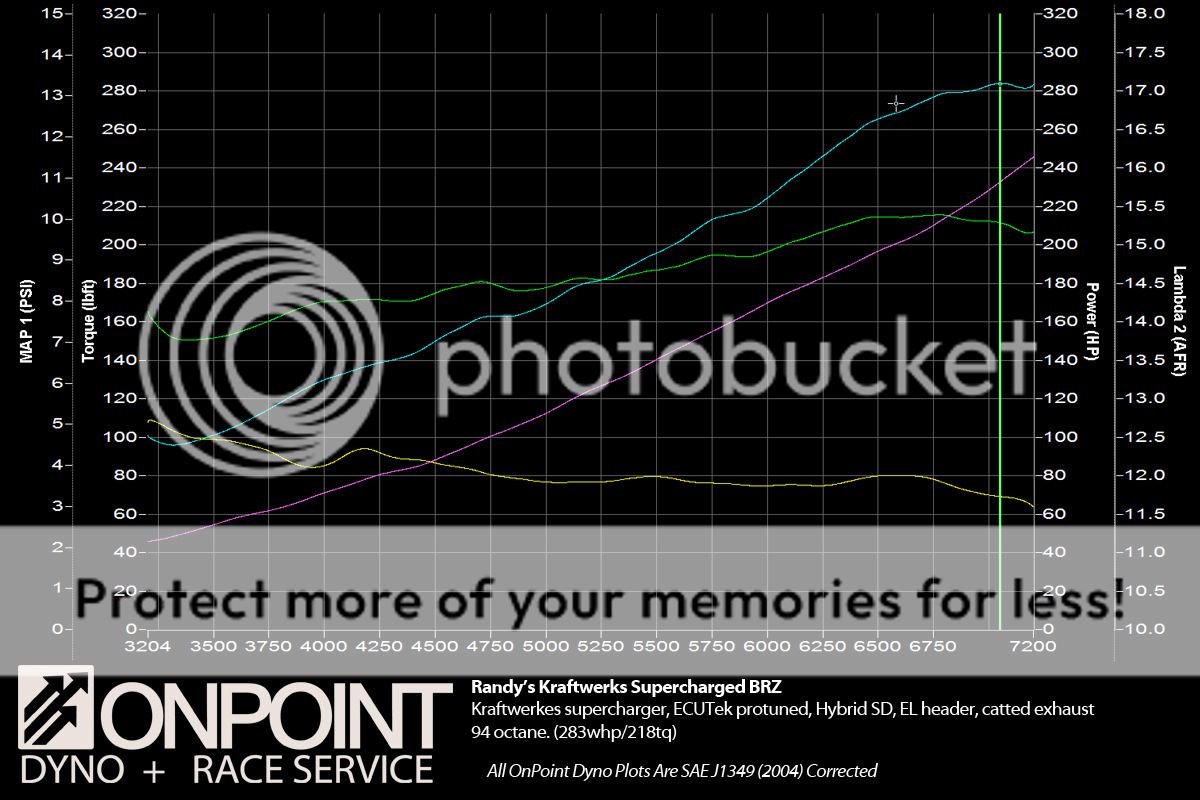

Concluding with Project BlueSky are the dyno figures. As we mentioned in part one, our goal was to produce safely as close to 300whp as we could get on pump fuel. As a recap, the stock BRZ/FRS baseline dyno produced under 150whp on the Dynapack system. In otherwords, we were looking to double the power output on this car. As for all of our dyno tuning, we enlisted our partner Sasha from OnPoint Dyno (https://www.onpointdyno.com/) to do the tuning on Project BlueSky.

Let’s take a look at what the car made and quickly go over some numbers. As you can see from the graph below we are all looking for that peak number. The car made 283whp and 218ft/tq on 94 octane. Some great aspects of the KW kit is just how smooth the power band is from 3100rpm all the way to redline. The power never really drops until redline so you have power constantly building, edging you to ring the car out as the revs build. Not only is this good on the track but it creates an exciting street driving experience as well. The flat to slightly rising torque curve also creates a very manageable power delivery to the rear wheels without suddenly having torque spikes creating unstable and uncontrollable power delivery. In turn, this makes the car easy to drive and an easy car to drive makes it a fast car to drive. From 150whp to 283whp, a very simple math figure increase of 133whp. That’s nearly double the amount of power. We are all very happy about the results and some more research/development on the garage side we are confident we could reach 300whp. I think it’s safe to say that a 280-300whp BRZ/FRS is something we can all smile about.

Although this concludes our Project BlueSky journal, we hope that this just a ‘just for now’ ordeal with this car. We at Touge Tuning thoroughly enjoyed working with the owner of BlueSky. We hope that down the road he will have more big plans for the car and we can keep adding to this journal and continue on with Part 5 and maybe even 6, 7, 8 ….. you never know!

Lastly, we’d like to thank all the companies and people involved with this build including Kraftwerks, Skunk2, Invidia, Clutchmasters, our partner Sasha at Onpoint Dyno and the owner of this beautiful BRZ for entrusting our services to build his dream car.

Brant Bergstrome

I would like to talk to you about doing this or something similar to my 2016 BRZ Hikari. I also have the 2016 WRX Hikari that could use some help. Thanks. Brant

Chris@TougeTuning

2 awesome cars Brant! Send an email to [email protected] and we can help you out.